WHAT IS 3D LASER SCANNING?

3D Laser Scanning:

The process of using lasers and cameras to measure the size and shape of logs or boards in a sawmill. You may also see it referred to as geometric scanning or geometric profiling.

Scanning delivers incredibly accurate information at production speeds.

Here’s how it works:

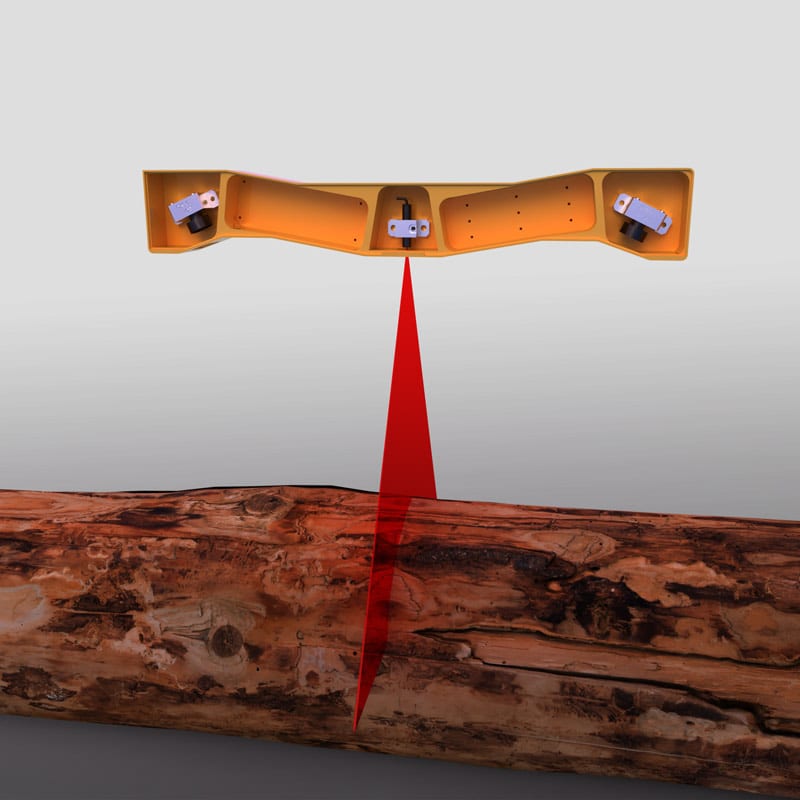

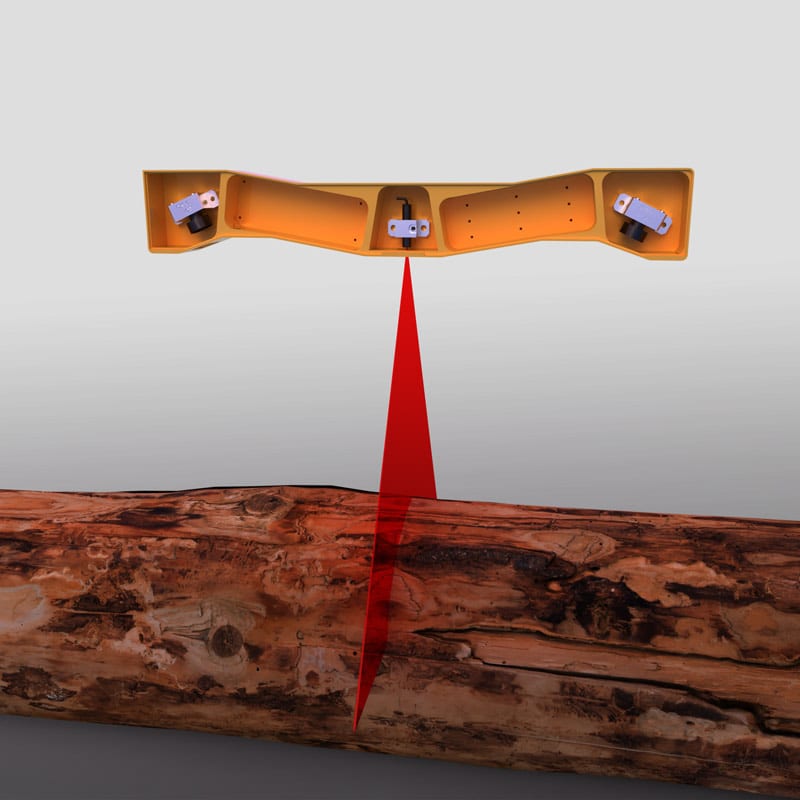

1 | Laser Projection

The scanner projects a laser line onto the wood.

2 | Camera View

The camera looks at the shape of the laser line.

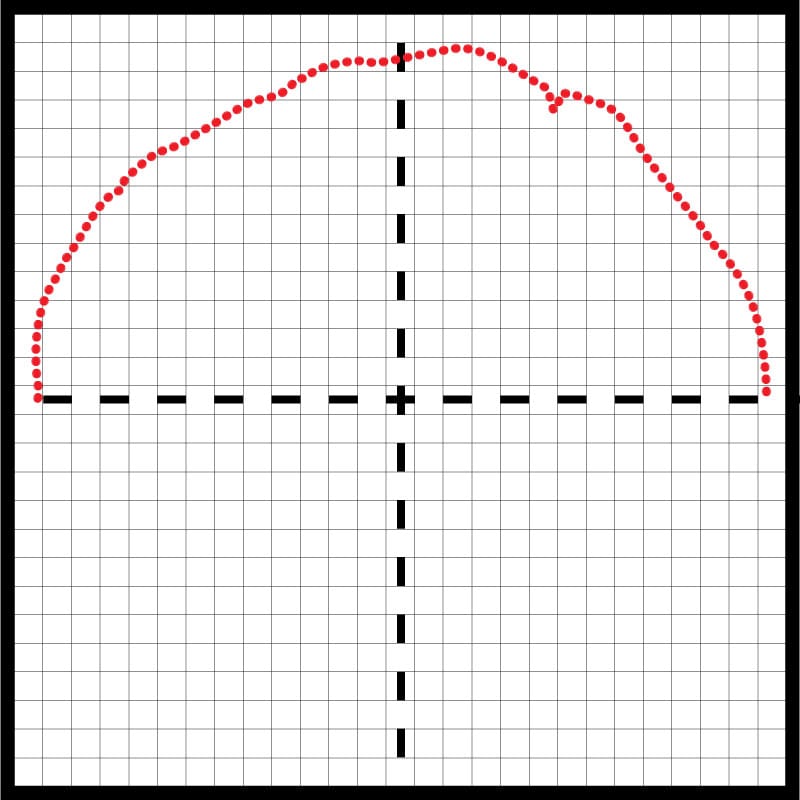

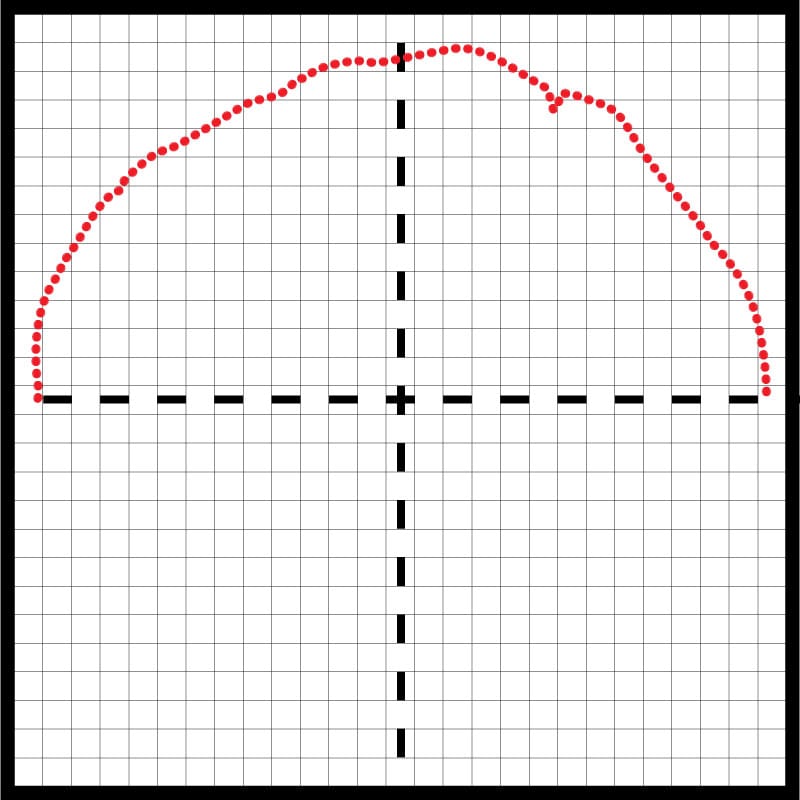

3 | Data Points

The laser shape is analyzed to produce coordinates of points.

The Sawmill Scanning Process

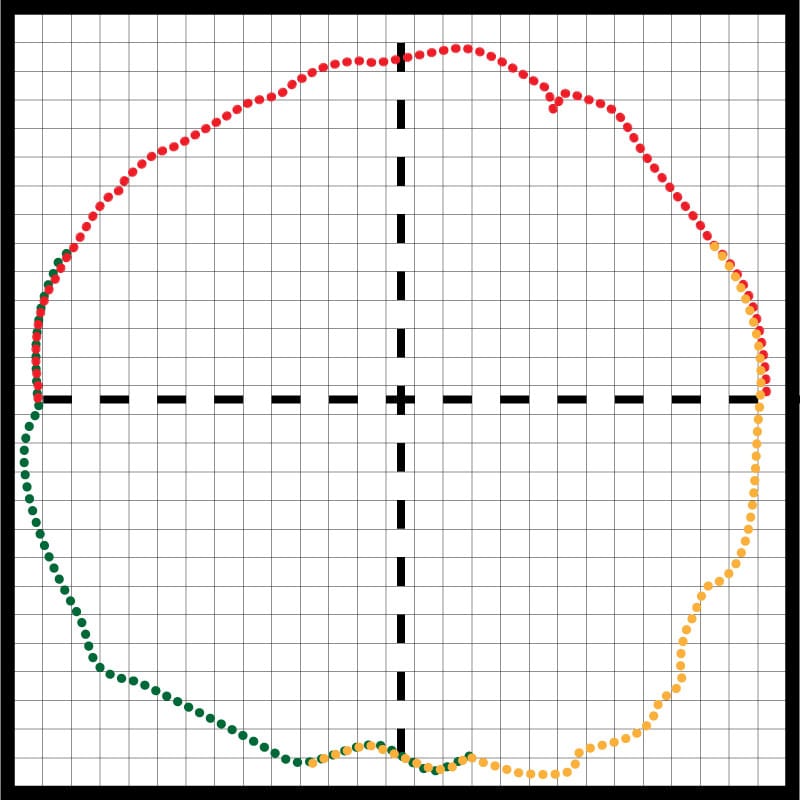

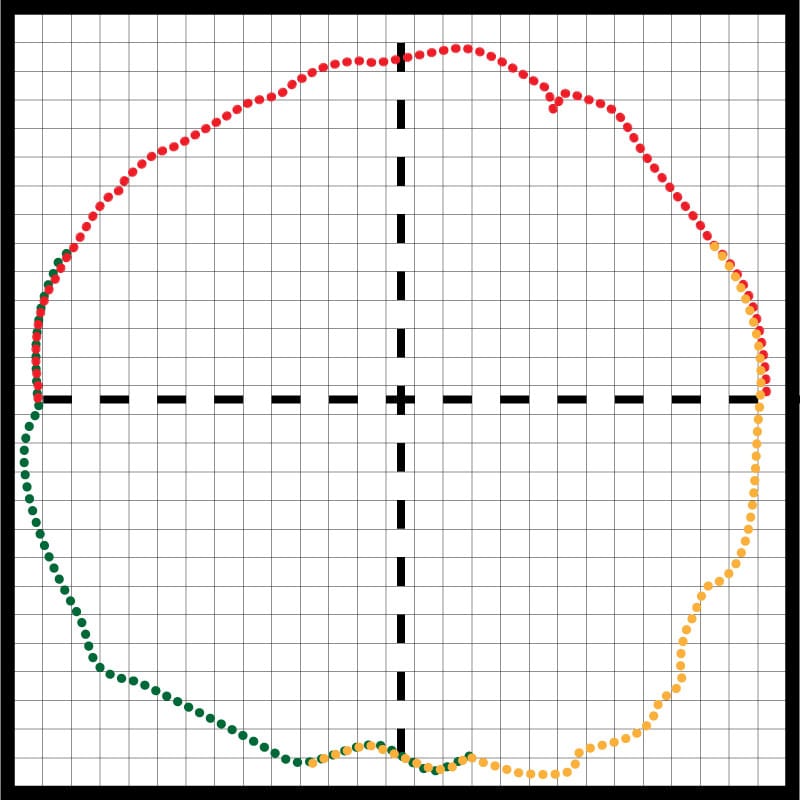

4 | Combine Points

Data points are combined from multiple cameras and other scanners.

5 | Model Generation

Merging points over time produces a complete 3D model.

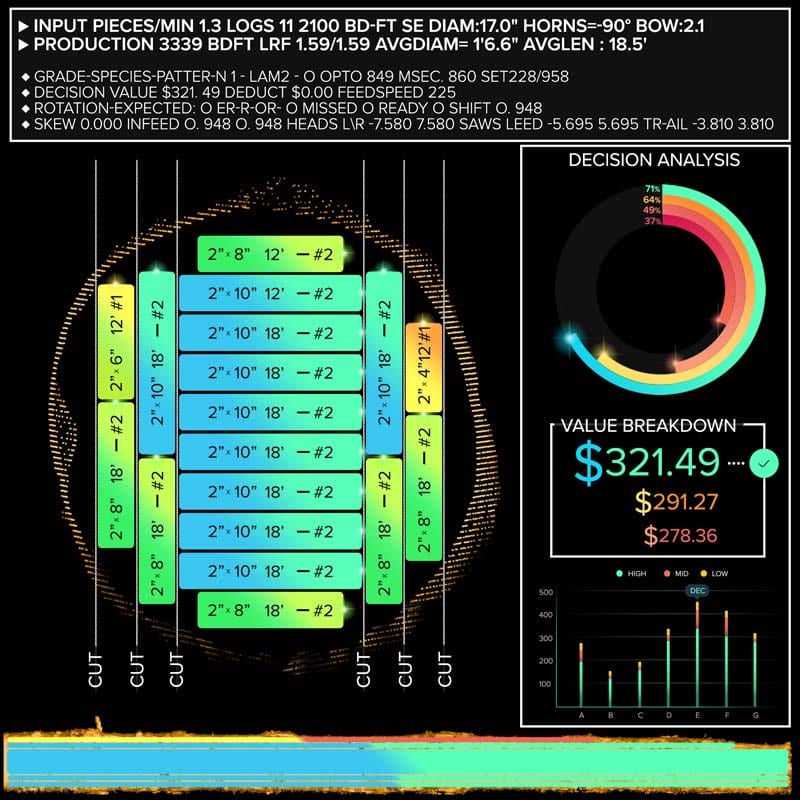

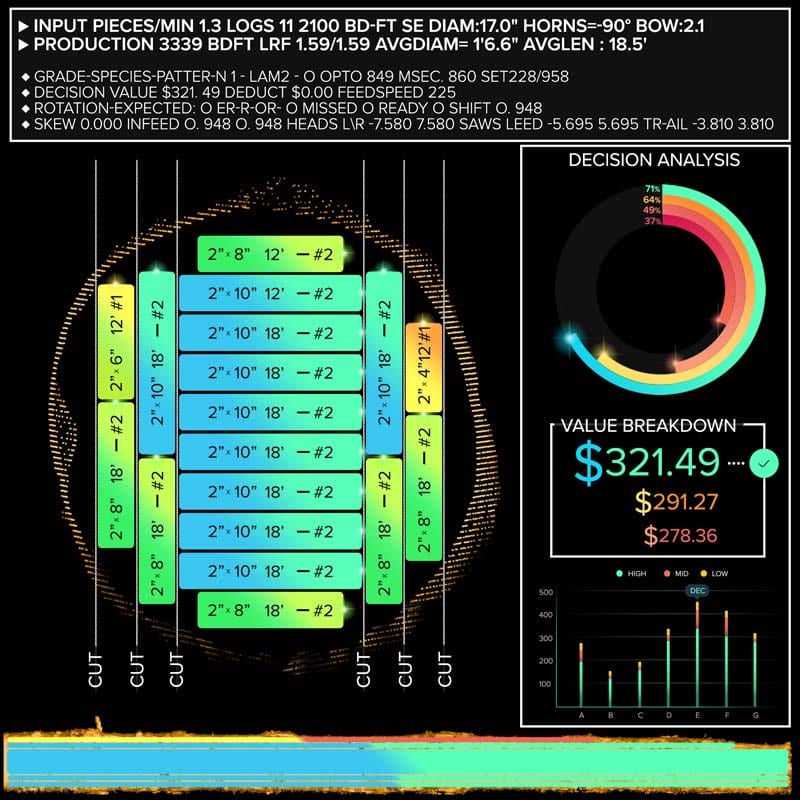

6 | Optimization

An optimization computer makes cut decisions based on the shape.

1 | Laser Projection

The scanner projects a laser line onto the wood.

2 | Camera View

The camera looks at the shape of the laser line.

3 | Data Points

The laser shape is analyzed to produce coordinates of points.

4 | Combine Points

Data points are combined from multiple cameras and other scanners.

5 | Model Generation

Merging points over time produces a complete 3D model.

6 | Optimization

An optimization computer makes cut decisions based on the shape.

WHY SHOULD YOU SCAN IN YOUR SAWMILL?

3D laser scanning gives you a much clearer picture of the wood that enters and exits each machine center in your sawmill.

Quality scanning allows optimization software to make the best decisions on how you cut.

This enables you to:

Improve Quality

Increase Yields

Reduce Waste

Maximize Value

The JoeScan Difference

From our design process to the decor in our lobby, these principles guide everything we do at JoeScan.

Simple solutions are easier to operate.

You need a partner you can count on to get the job done right.

Sawmills are tough places to work. We plan accordingly.

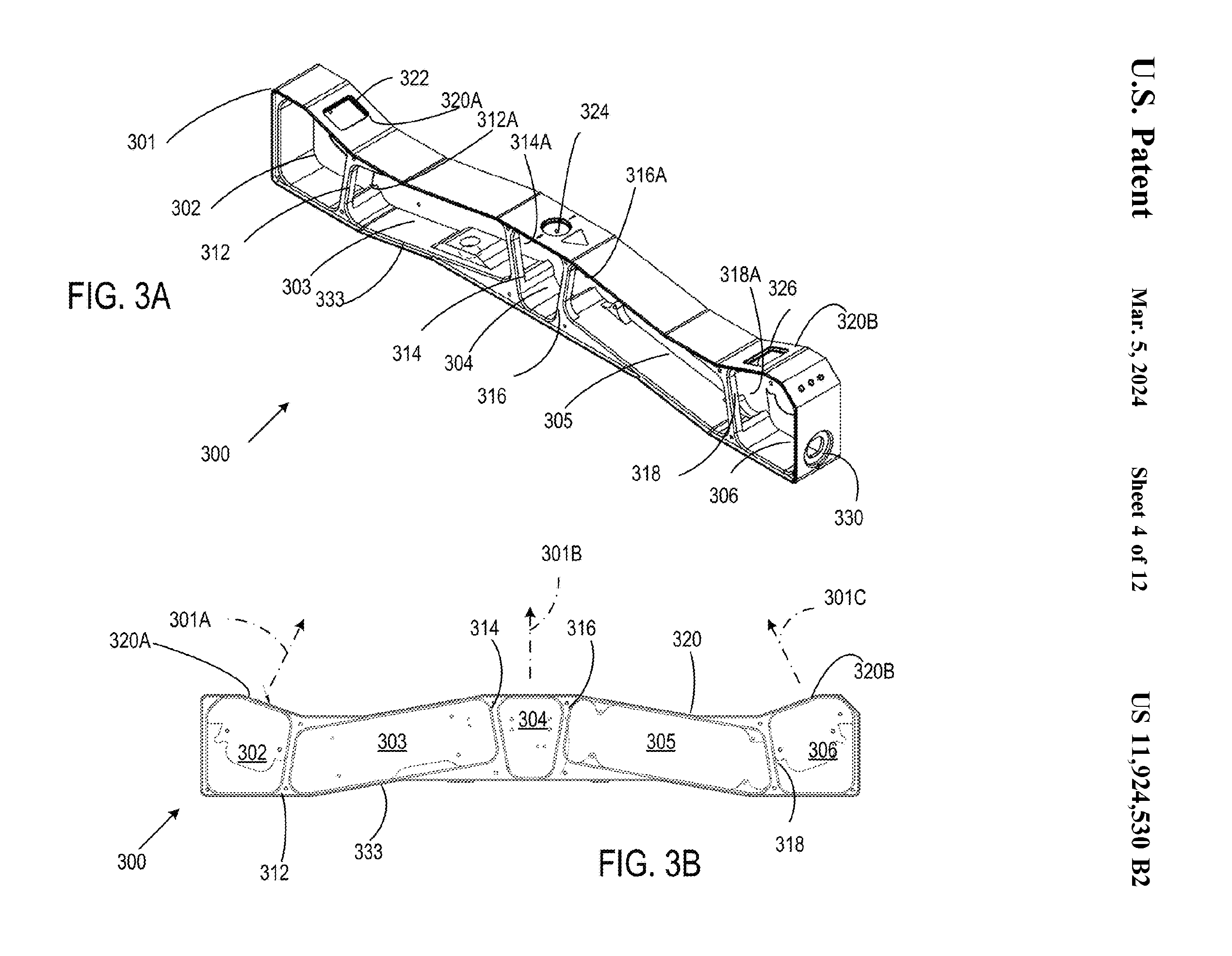

Patented Technology

All JoeScan JS-50 scanners are built with patented features designed specifically to improve sawmill scanning.

Support from our Engineers

There’s no call center “phone roulette” with us.

If you have a question, give us a shout. Because you deserve to get a speedy, knowledgeable response, you’ll get a real, live engineer on the horn.

Someone that knows the sawmill industry and understands your problem will help you find the solution you need, and fast.

Our Principles

Sawmills are complicated enough. The last thing you need is an overly complex scanner that is difficult to maintain and difficult to use. That’s why we strive to keep the complexity low and why we keep the operator in mind during every design decision.

|

“My guys love our JoeScans. They just work.” Jim Langdale Langdale Forest Products |

We know what downtime means to your mill. You need a scanning solution that won’t fail, so that’s what we make. Many of our earliest scan heads are still hard at work, over 20 years later. That’s quality you can count on.

|

“JoeScan scanners are bulletproof. Year after year, they withstand the rough sawmill environment with its sawdust, grease and vibration.” Randy Beard Seneca Sawmill |

We make scanners for sawmills, and for sawmills only. Our only focus is to create products that deliver results for our sawmill partners. How many other scanner manufacturers can say that?

|

“JoeScan scanners are reliable, stable, and have a long life. Those qualities, combined with the practical application and the result to our mill, set their scanners apart from the competition.” David Richbourg HW Culp Lumber Company |

Sawmills are complicated enough. The last thing you need is an overly complex scanner that is difficult to maintain and difficult to use. That’s why we strive to keep the complexity low and why we keep the operator in mind during every design decision.

“My guys love our JoeScans. They just work.”

Jim Langdale

Langdale Forest Products

We know what downtime means to your mill. You need a scanning solution that won’t fail, so that’s what we make. Many of our earliest scan heads are still hard at work, some 16 years later. That’s quality you can count on.

“JoeScan scanners are bulletproof. Year after year, they withstand the rough sawmill environment with its sawdust, grease and vibration.”

Randy Beard

Seneca Sawmill

We make scanners for sawmills, and for sawmills only. Our only focus is to create products that deliver results for our sawmill partners. How many other scanner manufacturers can say that?

“JoeScan scanners are reliable, stable, and have a long life. Those qualities, combined with the practical application and the result to our mill, set their scanners apart from the competition.”

David Richbourg

HW Culp Lumber Company

Unique Scanner Features

Pulsed-lasers

Prolongs the life of your scanner and gives greater placement flexibility.

QuikLock Mount

Lets you swap heads in seconds and removes the need for on-site calibration.

6x onboard lasers

X6B scans logs of any length in just 6 inches of travel.

Low-level API

Get the data you need, in the way you want it.

Single cable PoE

Just one cable on JS-50.

Half the cables = half the fuss.

5 year warranty

Along with our 10 year support policy.

NEED HUMAN HELP?

We’re always happy to answer your questions. Someone from our team will get back to you in a flash.

Error: Contact form not found.

NEED HUMAN HELP?

We’re always happy to answer your questions. Someone from our team will get back to you in a flash.

LET’S CHAT

+1.360.993.0069

Then

SALES

Press 2

REPAIRS

Press 3

ENGINEERING

Press 4

MADE TO BE

SIMPLE

MADE TO BE

RELIABLE

MADE FOR