IN THE SAWMILL

You can find JoeScans in over 300 sawmills around the world and you can find them scanning at every machine center.

SAWMILL MACHINE CENTERS

No two sawmills are exactly alike.

We strive to provide you with the very best scanner to help you achieve YOUR goals, no matter what saws you use to make your cuts.

That’s why our scanners are designed to deliver accurate data reliably, across a wide variety of sawmill applications.

THE DEVIL IS IN THE DETAILS

PRIMARY BREAKDOWN

3D SCANNING FOR

CARRIAGE HEADRIGS

The carriage headrig has continued to evolve with the industry – from manually operated to photo-cell arrays to front-side-only shape scanning. And today, complete-coverage 3-D scanning is the gold standard. JoeScan’s latest complete-coverage 3-D scanning is based on our next-gen JS-50 scanners, known for their simplicity, flexibility and reliability.

“Within two months of Pennyrile Sawmill installing a new carriage system with JS-25 X6Bs, it has increased production by 4-5% and has increased yield by at least 8%.”

Mahlon Grayber

Owner

Pennyrile Sawmill

FRONT AND BACK ADVANTAGE

By scanning both the front and back side of every log, our scanners provide the optimizer with a complete picture of the possible value of every log. The optimizer can then select a cut that maximizes that value.

FLEXIBLE PLACEMENT

Feedback from optimization engineers inspired a new, flexible-placement design for our X6B model scanners. This new design allows for convenient end-to-end installation of our carriage scanners, while still maintaining 6 inches between lasers. The final result is a simpler scanning system capable of scanning any length log in just 6 inches of travel.

BEST SCANNER FOR THE JOB

PRECISION PERFORMANCE

(WITHOUT THE EXPENSIVE UPGRADE)

(WITHOUT THE EXPENSIVE UPGRADE)

Many mills are finding that a short infeed JoeScan optimized sharp chain offers one of the best values around. You can get full auto-rotation and skew, with the low cost, easy maintenance and reliability of a sharp chain infeed. Previously, these benefits required million-dollar upgrades to huge and complex double-length infeed systems.

“Our old system in a high-impact area had to be recalibrated every day. After four years of working with JoeScan scanners, now I only check them once a month – and they’re just how I set them.”

Phil Loder

Process Controls Supervisor

Timber Automation & Control

OUTPUT THAT MATCHES YOUR OPTIMIZER

One of the biggest problems in any optimized system is ensuring the piece doesn’t move after it has been scanned. With a well-designed sharp chain infeed, you get a full 3-D scan of the log after it is fully impaled on the sharp chain, leaving minimal opportunity for the log to shift before hitting the saws. Customers with JoeScan scanning systems are continually amazed at how precisely the boards and cants coming out of their sharp chain match what the optimizer was attempting to produce.

IS YOUR SCANNING SYSTEM EFFECTIVE?

IS YOUR SCANNING SYSTEM EFFECTIVE?

The key test of any scanning system can be summed up with a single question:

Does your actual output consistently match what your optimizer claims? If not, then you have an opportunity to significantly improve recovery with a JoeScan system.

BEST SCANNERS FOR THE JOB

SECONDARY BREAKDOWN

3D SCANNING FOR

LINEAL EDGER INFEEDS

LINEAL-EDGER SCANNING IN A TIGHT SPACE

You want to go lineal. You want the low maintenance and high accuracy that only lineal scanning can give, but you just don’t think you have enough space. Well, it’s time to reconsider. JoeScan makes lineal scanning possible, even for short-coupled infeeds.

HOW DOES IT WORK

By having multiple scan zones, with each zone responsible for scanning just a portion of the board, you can get a full lineal scan with as little as six inches of travel. We know, because we’ve installed systems that do precisely that. Our scanners offer the flexibility to match the number of scan zones to your space and budget requirement.

“The JoeScan scanners on our TMT edger are very reliable – they operate consistently every day with little upkeep. They’re so reliable that sometimes we overlook routine maintenance on them. They’re sort of like a Timex watch: they take a licking but keep on ticking.”

Bruce Duncan

Mill & Maintenance Supervisor

Kane Hardwood

THE ORIGINAL LINEAL SCANNER

THE ORIGINAL LINEAL SCANNER

JoeScan helped pioneer lineal scanning. For years we’ve been hard at work delivering the best scanning for lineal systems. By focusing on the specific needs of sawmills, we’ve been able to deliver more of what customers want, while still remaining remarkably affordable.

STATE-OF-THE-ART AND SIMPLE? YES AND YES.

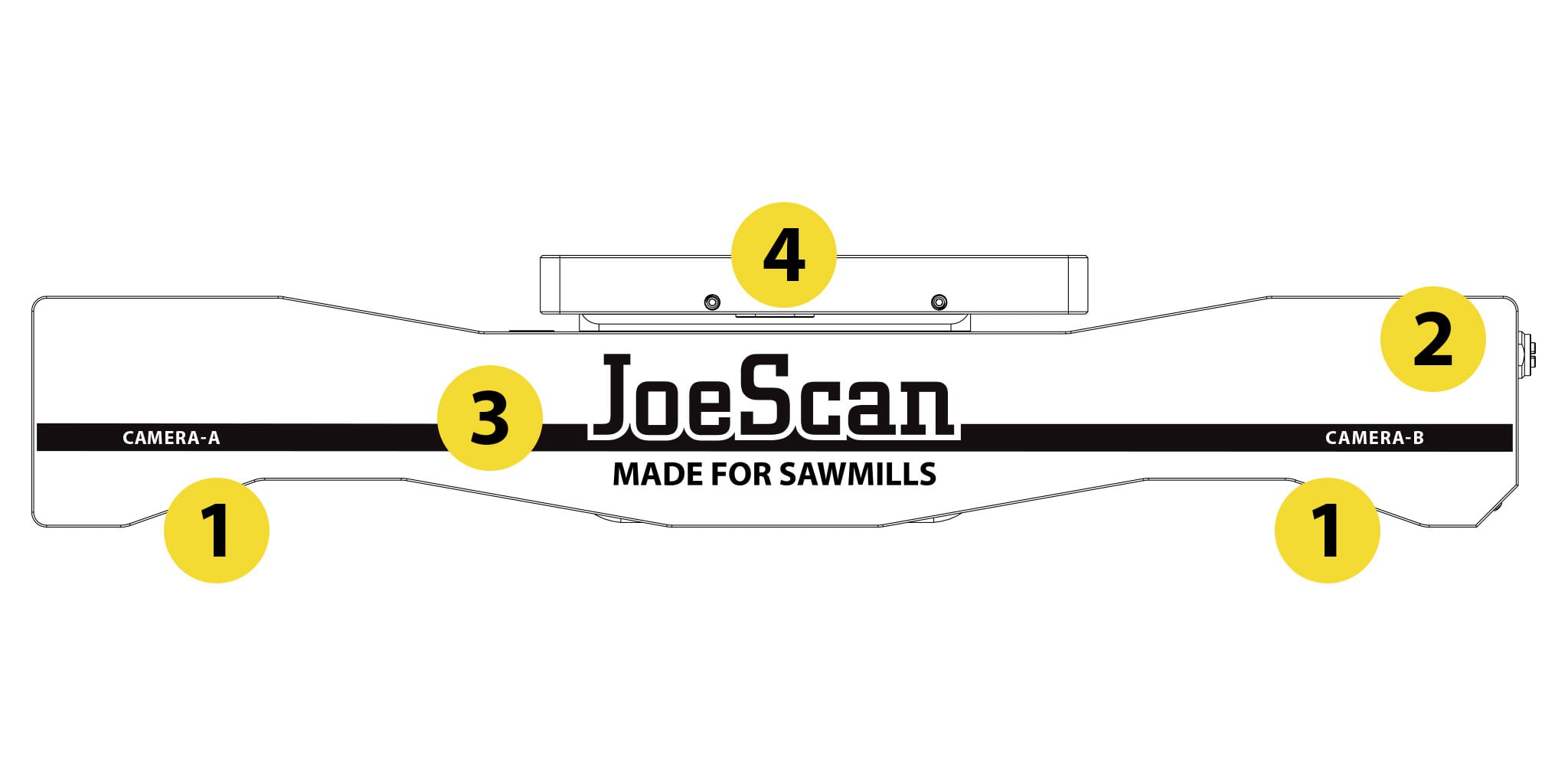

No doubt your sawmill wants the best technology, but technology that doesn’t solve real problems is just needless complexity. That’s why we combine leading-edge technology with real-world simplicity in our JS-50 scan heads.

| NEEDLESS COMPLEXITY | JOESCAN SIMPLICITY |

|---|---|

| Custom hubs, cables, and computer cards | Off-the-shelf Ethernet switches and cables |

| “No hot swap” warning stickers | Hot-swap day or night with no fear |

| Fiber-optic cable | Standard copper conductor cable |

| Additional computers for image processing | On-board image processing inside the scan head |

| Multiple cable runs per scanner | Just one Power Over Ethernet cable on our JS-50 |

| COMPETITOR COMPLEXITY | JOESCAN SIMPLICITY |

|---|---|

| Custom hubs, cables, and computer cards | Off-the-shelf Ethernet switches and cables |

| “No hot swap” warning stickers | Hot-swap day or night with no fear |

| Fiber-optic cable | Standard copper conductor cable |

| Additional computers for image processing | On-board image processing inside the scan head |

| Multiple cable runs per scanner | Just one Power Over Ethernet cable on our JS-50 |

| Scroll right for the JoeScan advantage |

BEST SCANNERS FOR THE JOB

TRANSVERSE APPLICATIONS

3D SCANNING FOR

TRIMMERS / SORTERS

THE EFFECTIVE SOLUTION FOR TRANSVERSE SCANNING

Transverse scanning has been a long-time challenge in need of a truly effective solution. Well, our JS-50 WX is not only an effective solution, it’s a simple one. The renowned reliability of JoeScan scan heads – no moving parts, fully sealed housings, intuitive set-up and Ethernet connectivity – makes the JS-50 WX the best combination of performance and price on the market.

“The JS-50 may have just proved multi-point lasers obsolete for 3D scanning applications.”

Jason Farmer

VP of Engineering

JoeScan

THE LINE LASER ADVANTAGE

What makes a JoeScan the best transverse scanner in sawmills today?

It begins with the laser.

The data density of point laser scanners in a transverse system is so widely spaced that it covers only a fraction of the board surface and misses features, but JoeScans use line lasers to deliver a thick blanket of data, eliminating the big gaps that lead to inefficient cutting decisions.

Other scan systems require additional sensors to determine accurate length, but our scanners deliver accurate length measurements directly.

While other scanners are unable to reliably distinguish steep wane from a clean edge, JoeScans do it easily, accurately determining width and wane points in both cases.

Bottom scanners in other transverse systems are positioned directly below the scan zone, which makes it difficult to keep them clean. JoeScan scan heads can be offset and placed under covers that keep material from falling directly on them while still delivering complete and accurate data.

THE REST OF THE BENEFITS

Transverse systems can also take advantage of the JS-50 WX’s other unique design features.

- Binocular camera system sees what single-cameras miss

- Just one PoE cable connector to run and connect (and protect)

- Next-gen speed and resolution delivers twice the specs of earlier generations

- Snap mount comes to you pre-calibrated

BEST SCANNER FOR THE JOB

NEED HUMAN HELP?

We’re always happy to answer your questions. Someone from our team will get back to you in a flash.

Error: Contact form not found.

NEED HUMAN HELP?

We’re always happy to answer your questions. Someone from our team will get back to you in a flash.

LET’S CHAT

+1.360.993.0069

Then

SALES

Press 2

REPAIRS

Press 3

ENGINEERING

Press 4

MADE TO BE

SIMPLE

MADE TO BE

RELIABLE

MADE FOR